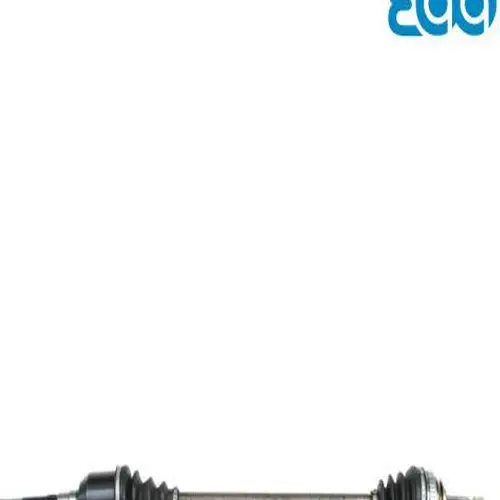

Premium Front Drive Shaft for BMW X4 F26 (2013-2018)

Product Description

Our high-quality front drive shaft is specifically designed for the BMW X4 F26 model years 2013-2018. Crafted from durable steel, this drive shaft ensures optimal performance and longevity. It meets the G16 balance standard at 3200 RPM, providing a superior driving experience. Whether you’re looking to replace a worn-out part or upgrade for enhanced performance, our drive shaft is the perfect solution.

Product Specifications

| Part Number | 2625719985, 26209425909 |

| Type | BMW X4 F26 2013-2018 |

| Material | Steel |

| Balance Standard | G16, 3200 RPM |

Explore Our Other High-Quality Products

EVER-POWER GROUP is your go-to source for a wide range of industrial products. Our offerings include:

- Agricultural gearboxes

- Power output shafts

- Sprockets

- Fluid couplings

- Worm gear reducers

- Gears and racks

- Roller chains

- Pulleys and timing pulleys

- Planetary gearboxes

- Bushings

We are committed to providing high-quality products at preferential prices, along with considerate services. Customers are welcome to customize drawings and samples to meet their specific needs.

Frequently Asked Questions (FAQs)

1. What models are compatible with this front drive shaft?

This front drive shaft is compatible with BMW X4 F26 model years 2013-2018.

2. What materials are used in the construction of the drive shaft?

The drive shaft is made from high-quality steel, ensuring durability and enhanced performance.

3. What is the balance standard of the drive shaft?

Our drive shaft meets the G16 balance standard at 3200 RPM.

4. Can I customize the drive shaft according to my needs?

Yes, customers are welcome to customize drawings and samples to meet their specific requirements.

5. What other products does EVER-POWER GROUP offer?

EVER-POWER GROUP offers a diverse range of industrial products including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and timing pulleys, planetary gearboxes, and bushings.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Front Drive Shaft

The front drive shaft is an essential component in a vehicle’s drivetrain, transmitting torque from the transmission to the front wheels. It ensures efficient power transfer and vehicle stability. Key performance characteristics include:

- Torsional Strength: The ability to withstand high levels of torque without twisting or failing.

- Durability: Made from high-strength materials, the drive shaft is designed to endure harsh conditions.

- Precision Engineering: Ensures smooth operation and minimizes vibrations, contributing to overall vehicle performance.

- Flexibility: Allows for slight movements and adjustments, accommodating the vehicle’s suspension and road conditions.

Types and Characteristics of Front Drive Shaft

Front drive shafts come in various types, each with unique characteristics suited for different applications. These include:

- Single-Piece Shaft: Ideal for short distances, known for its simplicity and strength.

- Two-Piece Shaft: Suitable for longer distances, incorporating a center support bearing for added stability.

- CV Drive Shaft: Features constant velocity joints, offering smoother performance and better handling.

Material Advantages of Front Drive Shaft

The materials used in manufacturing front drive shafts significantly impact their performance and durability. Common materials include:

- Steel: Known for its high strength and durability, suitable for heavy-duty applications.

- Aluminum: Lightweight and resistant to corrosion, offering improved fuel efficiency.

- Carbon Fiber: Provides exceptional strength-to-weight ratio, enhancing performance in high-performance vehicles.

Application of Front Drive Shaft in Various Fields

Front drive shafts are integral to several industries, reflecting their versatility and importance:

- Off-Road and Utility Vehicles: Ensures reliable power transfer, essential for rugged terrains.

- Construction Equipment: Provides the necessary strength and durability for heavy machinery.

- Industrial Equipment: Essential for the efficient operation of various industrial machines.

- Marine Equipment: Offers corrosion resistance and strength for maritime applications.

- Mining Equipment: Withstands harsh environmental conditions, ensuring consistent performance.

Future Development Trends and Opportunities

The front drive shaft industry is poised for significant advancements, driven by technological innovation and market demands. Future trends and opportunities include:

- Material Innovation: Development of new materials that offer enhanced strength and weight reduction.

- Advanced Manufacturing Techniques: Implementation of precision engineering and automation for higher quality and efficiency.

- Integration with Electric Vehicles: Adapting designs to meet the unique requirements of electric drivetrains.

- Sustainability: Focus on eco-friendly materials and processes to reduce environmental impact.

Choosing a Suitable Front Drive Shaft

Selecting the right front drive shaft involves several critical considerations:

- Determine Application Requirements: Understand the specific needs of your application to ensure compatibility.

- Evaluating Power Requirements: Assess the torque and power levels to choose a shaft that can handle the load.

- Check Speed and Torque Specifications: Ensure the shaft’s capabilities align with the operational demands.

- Measuring the Length of the Shaft: Accurate measurements are crucial for proper fit and function.

- Evaluate Connection Type: Consider the type of connections required for seamless integration with your vehicle.

- Check Safety Features: Ensure the drive shaft includes necessary safety features to prevent failures and accidents.

Conclusion

In summary, the front drive shaft is a vital component that significantly impacts the performance and reliability of various vehicles and equipment. Understanding its characteristics, types, material advantages, and applications can help in making informed decisions. As the industry evolves, staying abreast of future trends and selecting suitable drive shafts will ensure optimal performance and longevity for your specific needs.

Author: Dream